The other business model is to develop a product that serves a niche market very well and sell it to an established company. This strategy also works for established companies which wish to fill weak areas in their portfolios or acquire talented people. This happens often in the high technology industries – and it also happens in control and automation markets as well. Several companies have been busy on the acquisition front lately and two of note include Belden and GE. Belden recently picked up Byres Security, while GE acquired Commtest. Both acquisitions strengthen all the parties involved. Founded by noted cyber security expert Eric Byres and his wife Joann, Byres Security has developed a networking product incorporating Byres\‘ research into cyber security protection including defense in depth. The product, known as Tofino Security, will remain and the company will operate independently as a business unit under Belden. While Belden picks up an internationally known talent, it now also has a product to complement its Hirschmann line of networking equipment. The deep pockets of Belden will fund additional research and development for a continuation of new security products. Meanwhile GE picks up Commtest, a New Zealand based provider and designer of machinery health information systems. This will complement GE Energy\’s Bently Nevada product line of machine condition monitoring systems. Bently Nevada provides machinery protection and condition monitoring for refineries, petrochemical plants, power plants and wind farms. As a major component of predictive maintenance, condition monitoring is essential to increase asset longevity. Through condition monitoring, plant managers constantly receive data that provides input about the health of their machines. Commtest is based in Christchurch, New Zealand, and primarily focuses on producing vibration analysis and monitoring equipment. Vibration analysis detects early signs of impending machine failure so managers can proactively do direct repairs and make replacements before they encounter expensive failures. The business model that does not work out very well is the mating of two elephants, so to speak. The AOL/Time Warner was a disaster. One wonders at what would have happened had the mating dance of Microsoft and Yahoo come to fruition. In the automation market, that translates into the continued belief that Invensys and/or Rockwell Automation are not viable long term unless sold to become parts of larger enterprises. Those pundits who hold that view look at the deep pockets of Siemens as a likely purchaser. I am not in that camp. Those huge acquisitions seldom work. The indigestion caused for the management team that undertakes such a sumptuous feast would be life threatening. I think we will see continued startups as entrepreneurs develop new niche solutions for industrial automation and companies searching to complete their portfolios such as ABB, Belden, GE, Rockwell Automation, Schneider Electric and Siemens continue to evaluate their prospects. This will make for a healthy automation and controls market.

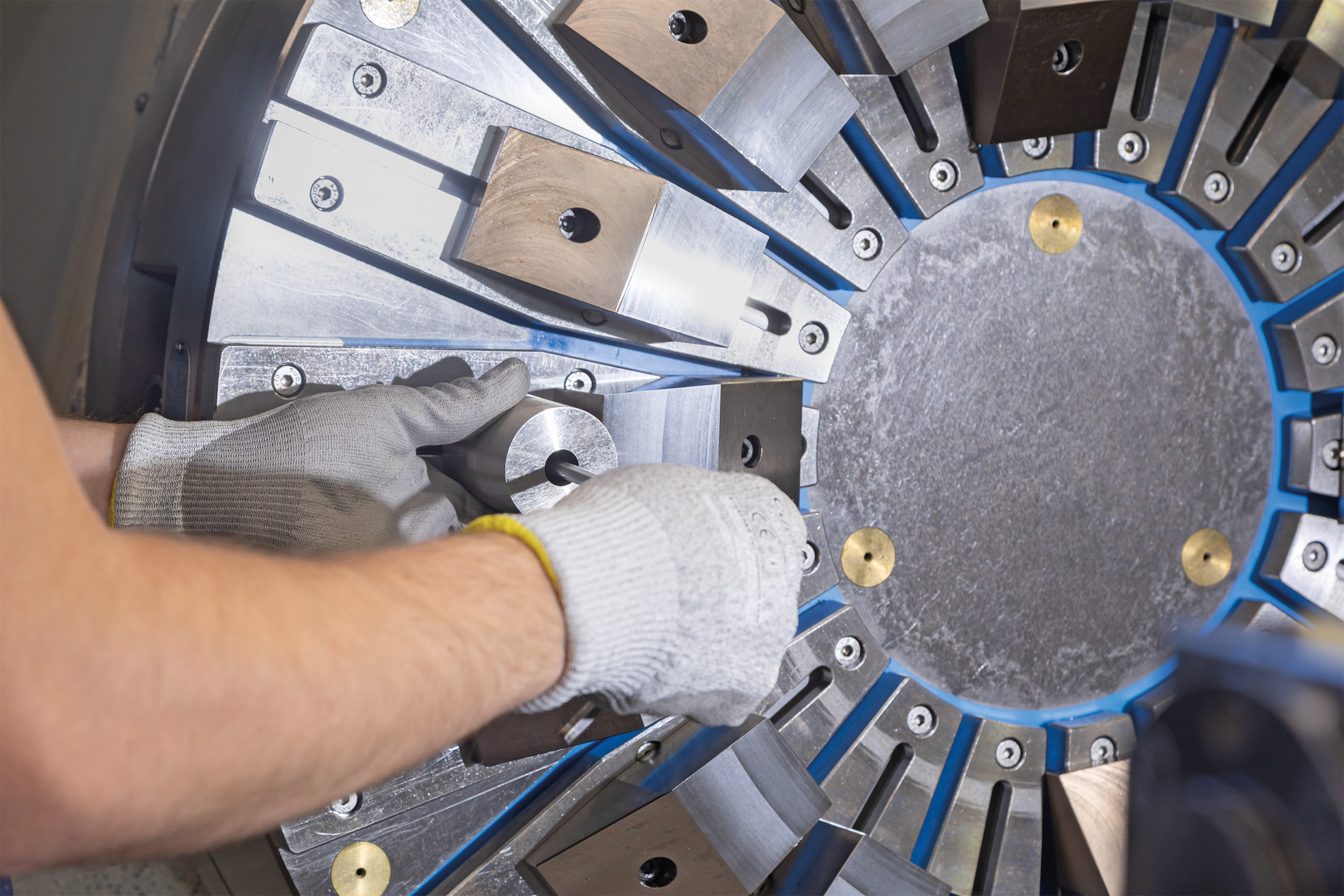

Gute Stimmung auf der Control 2024

Zur 36. Control, die vom 23. bis 26. April stattfand, kamen 475 Aussteller.