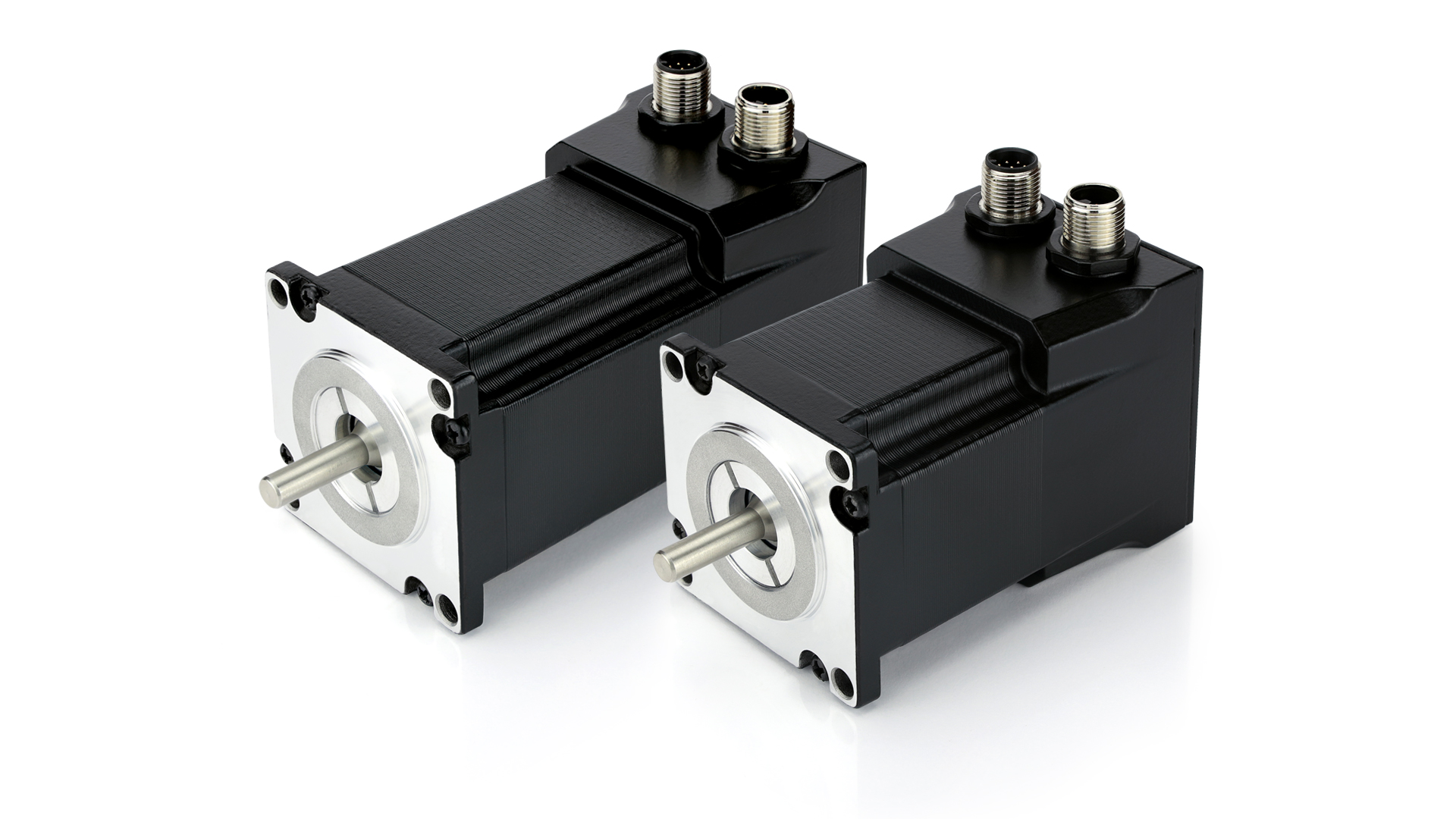

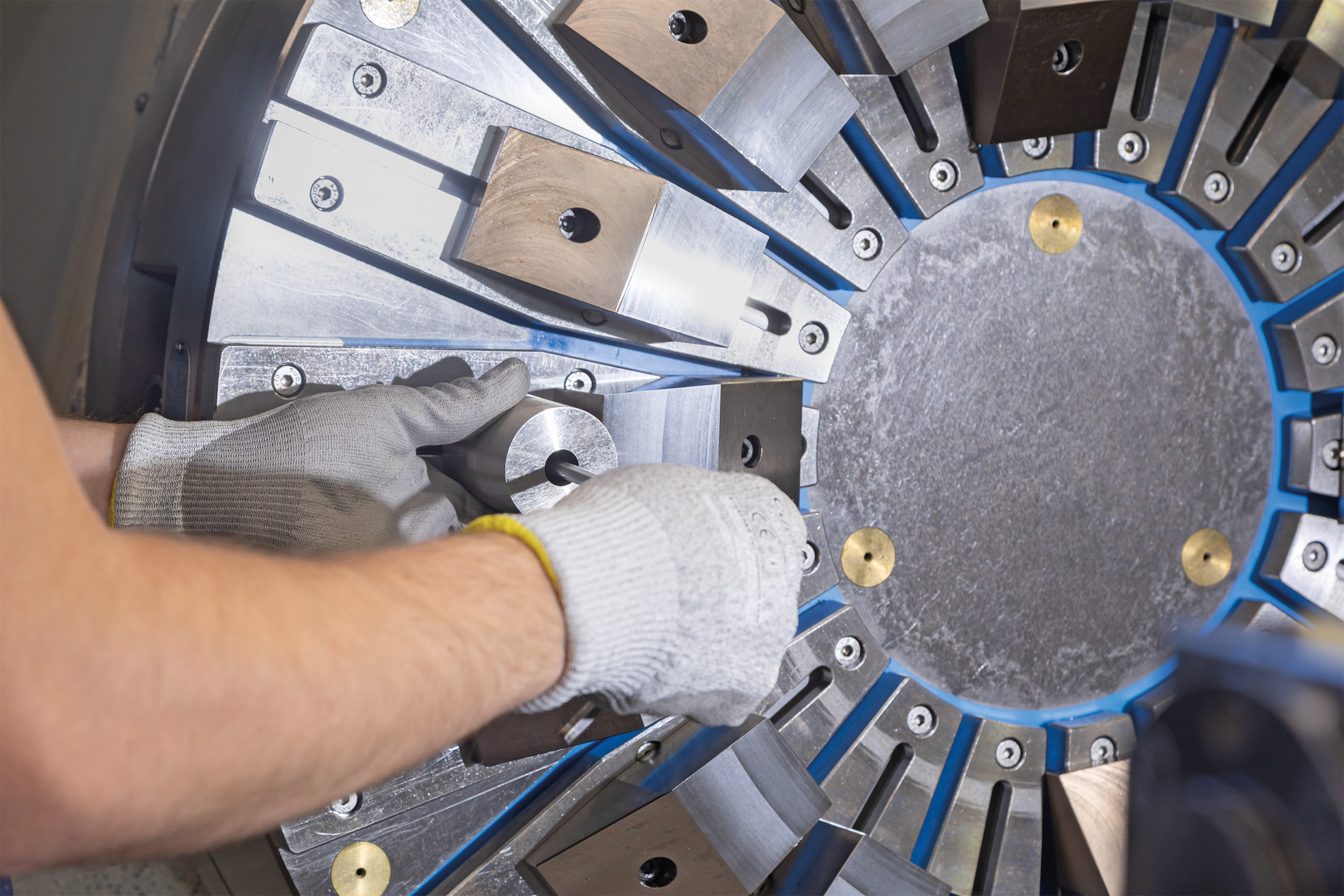

We\’re already beginning to hear more and more evidence that increasing numbers of young people are getting trained and being gainfully employed in the manufacturing industries. But there\’s still a long way to go, of course – after all, you can\’t turn around decades of negative news about manufacturing employment in the space of a few years. To help address this issue, PMMI, the Association for Packaging and Processing Technologies (and the parent company of Automation World), has announced the release of Motors and Motor Controls, the newest test in its mechatronics certificate program. PMMI launched its Mechatronics Certificate Tests in 2010 to address four key areas of modern manufacturing technology: mechanical, electrical, controls and computer science. Currently, PMMI offers six tests and will add a second Programmable Logic Controllers test later this year. The newly released Motors and Motor Controls test is designed for intermediate-level tradespeople, technicians and technologists. It assesses their mastery of principles, application, troubleshooting and maintenance of rotating electrical motors and electronic motor drives used in packaging and processing. There are no prerequisites for this test; however, test takers are expected to have passed PMMI\’s Industrial Elec-tricity 1 and Industrial Electricity 2 mechatronics tests or have equivalent knowledge and experience. The Mechatronics Certificate Tests offered by PMMI are part of the Manufacturing Skills Certification System endorsed by the National Association of Manufacturers (NAM). \“This series of stackable credentials helps manufacturers identify the qualified, skilled talent they need for today\’s in-demand technical jobs,\“ says Maria Ferrante, vice president, education and workforce development, PMMI. \“Each person who successfully passes a PMMI mechatronics test receives a nationally recognized certificate.\“ Stephan Girard, director, workforce development, PMMI, adds, \“PMMI\’s Mechatronics Certificate Tests are powerful tools to assess the technical skills of your employees and pinpoint any areas for improvement.\“ Girard facilitated the development of the Motors and Motor Controls test with subject matter experts from PMMI member companies and technical schools and colleges that offer packaging curricula. Earlier this year, PMMI partnered with the Industrial Maintenance Training Center of North America, in cooperation with the Employment and Training Administration of the U.S. Department of Labor (DOL), to create National Apprenticeship guidelines for the occupation of mechatronics technician. This apprenticeship program is based on PMMI\’s Mechatronics Certificate Tests, and employers can use the new apprenticeship guidelines as part of a formal, DOL-registered apprenticeship program or as a structure for their internal programs. PMMI works with a growing number of education and industry partners to advance this program. If your school or company would like to be a part, contact Stephan Girard at sgirard@pmmi.org.

www.automationworld.com