Some acquisitions don\’t work out. That has happened a few times to Siemens in the U.S. One acquisition has – the acquisition of UGS five years ago and the formation of Siemens PLM. Chuck Grindstaff, Siemens PLM president and CEO, opened the Siemens PLM user conference May 7 welcom-ing 1.800 plus attendees to what was called the longest running user conference of its type. There were over 400 sessions to educate scheduled, one of which I had the privilege to moderate. Grindstaff said that the five years of Siemens ownership has given the company tremendous benefit as shown in the company\’s growth over the time. The significant announcement made was that the company has initiated a vertical solutions support organization in order to work more closely with customers in those industry segments. Eric Sterling, senior vice president, general manager, Lifecycle Collaboration Software, a recent report said that we are about to enter the Third Wave of Manufacturing and it is the coming of digital and software. \“We\’ve been there already\“, he concluded. The third wave of manufacturing is the digital revolution. Siemens PLM is at the forefront of that digital revolution. Six years ago, Siemens executives explained to me their vision of \“digital manufacturing\“ or the \“digital factory.\“ At the time they were developing a partnership with UGS, while rival Rockwell Automation was doing the same with Dassault Systemes. Siemens brought the digital product design company into the fold soon after, while the Rockwell/Dassault partnership has been something of an \“on again / off again\“ dance. PLM stands for Product Lifecycle Management. Its origins are in the computer aided design, or CAD, technology. Once a product is defined digitally, the idea is to make that digital data available to other digital applications, such as computer aided engineering (CAE) and computer aided manufacturing (CAM). Eventually digital data from automation and controls can be integrated. At this point, engineers can simulate the operations of an entire manufacturing line or even an entire plant digitally. All the interferences and workflows, not to mention the controls programming, can be worked out in advance of cutting the first piece of steel. This means a production line that is built and operational more quickly. A production line that builds products sooner means more profits to the company. This is an important revolution. The promise of PLM and the digital revolution are not fulfilled, yet. Challenges remain. I had a private interview with Grindstaff where he described for me the challenges of abstracting data from the software application such that the data can be used by other applications. It is happening now, but there is still much work to do. Meanwhile, Siemens PLM announced some new products. One is the release of Teamcenter 9. This release adds a new integrated systems engineering solution and tightens the integration across the unified architecture. This enables a common view of the system up and down the value chain. Further, the enhanced integration of content management in Teamcenter 9 allows product documentation to be created in parallel with the design process. Active Workspace is an intuitive, highly visual and personalized environment for accessing intelligent 3D information. Active Workspace is another important step towards realizing Siemens PLM Software\’s High Definition PLM (HD-PLM) vision, which was established to help decision makers make better informed decisions more efficiently and with a higher level of confidence. Keynote presentation on Day Two of the event focused on the need to educate a future workforce. Not just a U.S. problem, data shows that there were 3 million new engineers needed globally in 2010, while only about 2,25 million were graduated. Siemens PLM is working with organizations that try to interest young people in science and engineering careers.

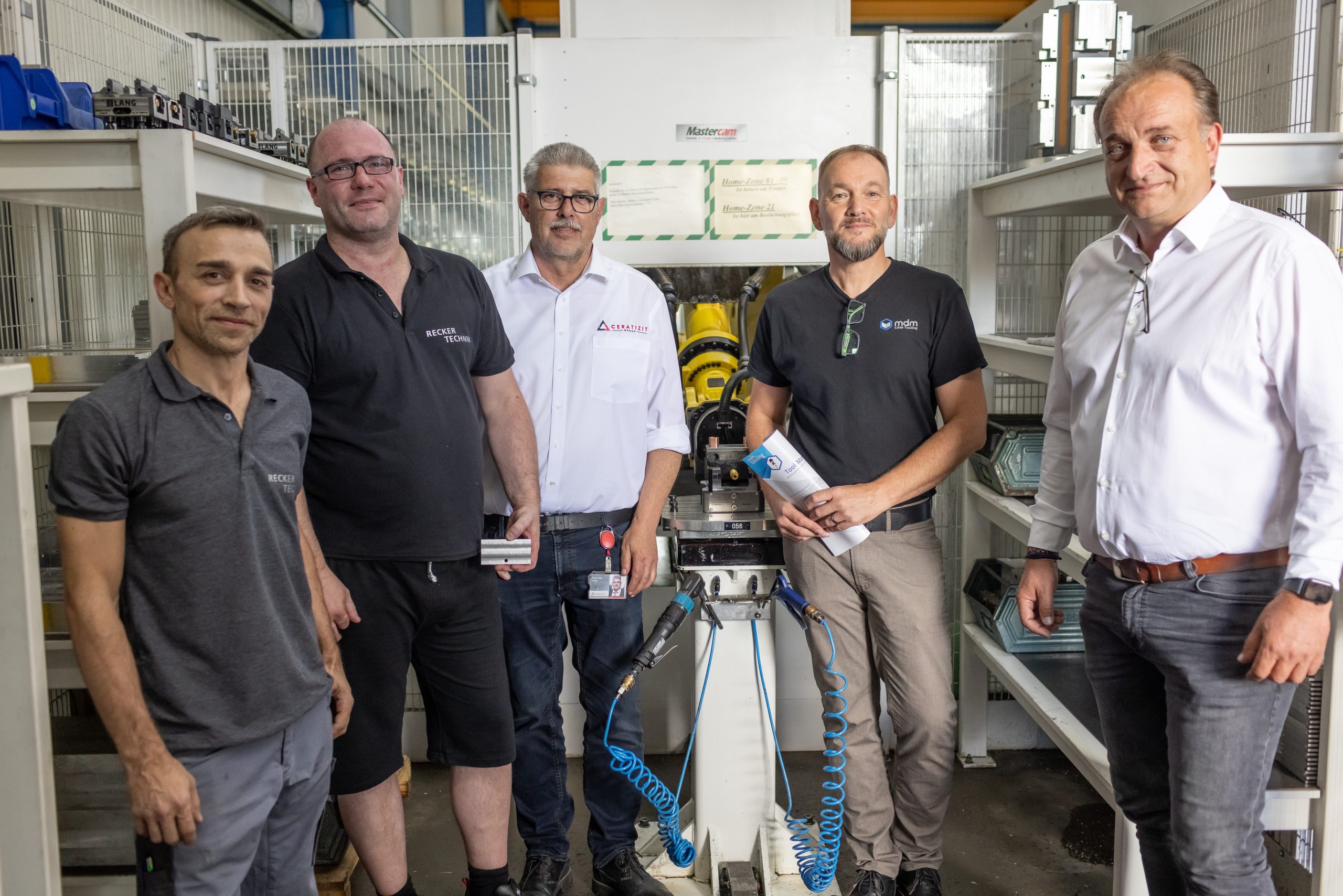

Gute Stimmung auf der Control 2024

Zur 36. Control, die vom 23. bis 26. April stattfand, kamen 475 Aussteller.