ESA International is the association that promotes execution level (level 3 as it is known) software. At the North American conference, leaders outlined a new strategy targeting membership development and education. The organization is seeking to get the message to \’C-level\‘ executives about the importance of software at this level to the overall performance of manufacturing operations. It is also working with implementers on best practices. The European Conference is 9-10 November in Jaarbeurs, Utrecht, The Netherlands. Pack Expo is the annual trade show of the Packaging Machinery Manufacturers Institute (PMMI). While decidedly North American in emphasis, several international machinery manufacturers also exhibited. The larger Expo is held biennially in Chicago. This year is the so-called \’off year\‘ held in Las Vega for only three days rather than the four-day Chicagoshow. Many automation suppliers were present. In \’The More Things Change, The More They Stay the Same\‘ department, once again I went from booth to booth of automation and controls suppliers who predicted the imminent demise of Rockwell Automation as the dominant North American supplier to packaging machinery manufacturers. (Just substitute \’Siemens\‘ for \’Rockwell\‘ in Europe I would imagine.) If you look purely from a product point of view, they have an argument – and they all made it forcefully. There is no doubt that such suppliers as Beckhoff and B&R Automation not to mention Bosch Rexroth and Schneider Electric have capable products. The question is more one of sales and marketing. How do they convert perennial grumbling about Rockwells pricing or products into actual sales? To date, I have not seen much movement. But…you never know. This might be the year where someone puts a dent in the market share. OMAC, formed as an end-user organization promoting control interoperability and standardization and re-formed as a joint vendor/user organization promoting interoperability, was seemingly resurrected from the ashes at this event. Under vigorous leadership of Nestle engineers who foresee great benefits of suppliers and machine builders adopting the PackML series of specifications, several meetings were held, new committees were formed and the energy and enthusiasm of the new direction and leadership was evident to the few journalists who attended the press conference following. It sounded good. Hope they find their way. Meanwhile, at the Profibus International North American conference, three speakers went into detail about why they chose Profinet over its rival. One common theme – organization. The PI-NA leadership works hard to provide marketing support, partner recruitment and help on technical issues that all three speakers valued. The speakers were from VW, Chrysler (which standardized on Siemens and Profinet) and GE Intelligent Platforms (which also standardized on Profinet). Just as I was writing this column, I took time for a media event with Harting. The owners were in the Chicagoarea to celebrate 25 years of USpresence and the expansion of manufacturing capability here.

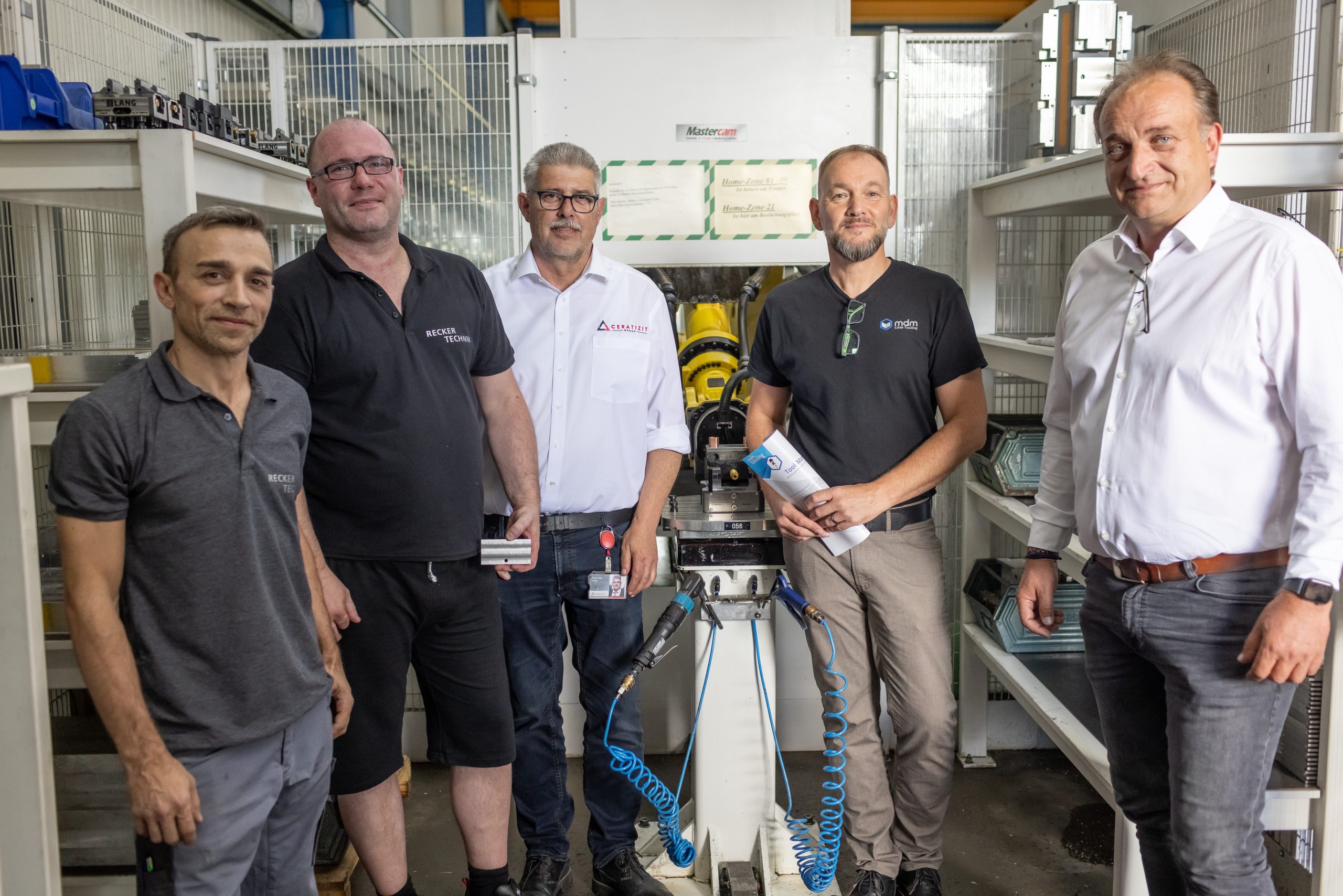

Gute Stimmung auf der Control 2024

Zur 36. Control, die vom 23. bis 26. April stattfand, kamen 475 Aussteller.